- Home

- Products

- Packing Machine

- Wire Forming Machine

- Food Processing Machine

- Flour Milling Machine

- Garlic Processing Machine

- Onion Processing Machine

- Potato Processing Machine

- Ginger Processing Machine

- Banana Processing Machine

- Carrot Processing Machine

- Peanut Processing Machine

- Chili Processing Machine

- Corn Processing Machine

- Dates Processing Machine

- Coconut Processsing Machine

- Meat Processing Machine

- Fruit & Vegetable Processing Machine

- Fruit Grader Machine

- Woodworking Machine

- Boilers

- Recycling Machine

- Laundry Room Machine

- Paper Processing Machine

- Video

- About Us

- Contact Us

Date:January 23, 2015

Waste Tyre Pyrolysis to Oil Plant

Table of Contents

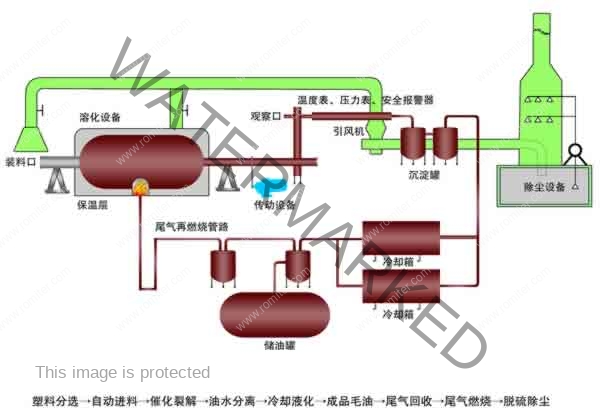

Pyrolysis to Oil Plant Working Process

- Waste Plastic Recycling Flow: plastic separation → automatic feed → catalytic cracking→ oil-water separation → cooling liquid → crude oil → flammable gas recovery → flammable gas combustion → desufuration and dust removal

- Waste Tires Recycling Flow: tire broken → automatic feed → catalytic cracking → oil-water separation → cooling liquid → carbon black emission → carbon black processing → crude oil → flammable gas recovery → flammable gas combustion → desulfuration removal.

Main Tyre Pyrolysis Plant System

Heating System

Reactor Using Q245R boiler plate and the thickness is 12mm, 14mm, 16mm , the thickness would be changed according the customers’requirments.

The main engine use horizontal-type of 360°structure-0.8 r/min

Separation System

Gas separator & Depositing tank

Depart the heavy oil and impurities from the oil gas to purify the oil.

Condensing System

Generally speaking , for all the raw material all be finished by heating to gasification and cracking, and then cooling to get oil, so they key is the relationship between the yield rate and condensation. So the best and easy way is to increase the condense area so as to get higher yield rate.

Dedusting System

Desulfurization dedusting, Water film cyclone

Desulfurization dedusting:remove the sulphur(when use coal as fuel) and dust

Water purification: for the second removal.

Waste Gas Recycles System

Water seal & Spray fire gun

In the process of refining oil, when the gas is heated up to 150 , it will produce a large amount of gas CH4&C4H8 ,which cannot convert to liquid at normal temperature and normal pressure. However, these gases can be used as fuel, which is not only environment protection but also energy conservation

Carbon Black Recycles System

Heaving dragon screw conveyer

The solid residual will be left after the catalyst splitting from scrap plastic, approximately take up 5% to 10% of the waste tire.

Its main component is the black carbon, which can be used as raw materials in industry, as well could be mixed with the pulverized coal ash to produce the raw material of the thermal power plant, and also could be applied to the manufacturingof the pulverized coal ash brick (one kind of environmental protection building material).

Output Products Percentage

| Crude oil | Carbon Black | Steel Wire | Gas |

| 45%-55% | 30%-35% | 10%-12% | 8%-10% |

Application

The Usage of Final Production ——Fuel Oil

Fuel oil from waste tyre are used in below industries:

- Power plant factory

- Glass factory

- Cement factory

- Ceramic factory’

- Aluminum factory

- Boiler factory

- Central heating factory

- Painting factory

The Usage of Final Production —— Carbon Black

Carbon black from waste tires are used in below industries:

- Electric cable jacketing

- Conveyor ban

- Hose and doormat

- Black nylon bag

- Rubber additive

- Automatic spare parts

- Heat Isolation

- Black colorant in rubber materials

- Plastic pipes

- Industries rubber products

- Fire fighting

Steel wire from waste tires can be re-sale to steel factory.

Profitability Analysis

Take waste tires oil refining equipment processing 10 tons for example:

| No. | Item | Cost of Per Batch |

| 1 | 10 tons of waste tires | 10T×1500 RMB/T=15000 RMB |

| 2 | 0.4 tons of coal | 0.4T×800 RMB/T=320 RMB |

| 3 | Water and Electricity | 200×1.00 RMB=200 RMB |

| 4 | Workers | 4×100 RMB=400 RMB |

| 5 | Total Cost | 15920 RMB |

| No. | Item | Income |

| 1 | Crude Oil | 10T×45%×4500 RMB=20250 RMB |

| 2 | Carbon Black | 10T×35%×520 RMB=1820 RMB |

| 3 | Steel Wire | 10T×13%×2200 RMB=2860 RMB |

| 4 | Gross Profit | 24930 RMB |

| 5 | Daily Net Profit | 24930 RMB-15920 RMB=9010 RMB |

| 6 | Monthly Net Profit | 9010 RMB×25=225250 RMB |

| 7 | Yearly Net Profit | 225250 RMB×10=2252500 RMB |

Safety

- Professional sealing technology for cover, oil outlet.

- Heavy oil is separated which can avoid the problems of jam in later condensing.

- Vacuum system will prevent exhaust gas from going back to reactor and causing accident.

- Alarm, safety valves, thermometer, pressure gauge and safety valve.

- It is dangerous to burning exhaust gas (C1 to C4). In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

After service

Installation and Training: Our Company will send 1 technician for guiding your installation, testing the machine and training your workers. The installation period shall be 20 days. You shall pay salary for the technician with $50 per day and also the round-trip ticket and accommodation.

Warranty:

1). the reactor guarantee period shall be 60 months.

2). Transmission Equipments guarantee period shall be 36 months.

3). Valve, meter and switch box guarantee period shall be 24 months

Email: info@romiter.com

Copy Right@ 2006 All Right Reserve